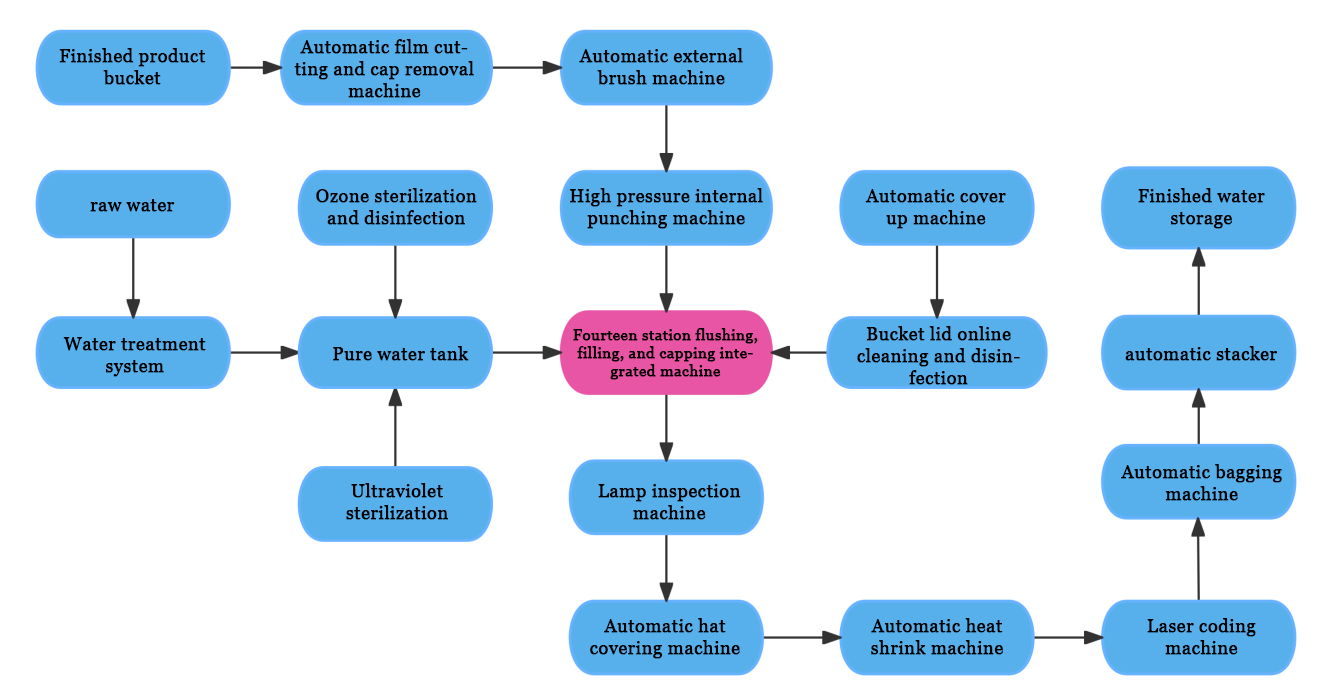

How Does the Core Filling Process Work?

What Advantages Can Barrel Factories Expect?

● High Efficiency and Throughput – The system is designed for continuous operation with synchronized washing, filling, and capping processes, ensuring your drinking water production line handles large volumes of barreled water with minimal downtime.

● Hygienic and Safe Operation – Fully enclosed design and automated handling reduce contamination risks, maintaining food-grade hygiene standards throughout the production process.

● Energy and Water Savings – Advanced control systems optimize water usage and energy consumption during barrel washing and filling, lowering operational costs while supporting sustainability goals.

● Easy Maintenance and Durability – Built with high-quality stainless steel and durable components, the line is easy to clean, maintain, and operates reliably for years.

● Flexible Production – Capable of handling different barrel sizes and specifications, allowing the barrel factory to adapt to market demand without extensive reconfiguration.

● Reduced Labor Requirements – Automated processes significantly reduce manual intervention, freeing staff for other tasks while maintaining consistent product quality.

Which Auxiliary Devices Complete the Solution?

● Precisely positions lids for fast and accurate capping.

● Reduces misalignment errors and minimizes product waste.

● Compatible with multiple lid types and barrel sizes.

● Integrates seamlessly with the main filling line for smooth operation.

Automatic Film-Cutting and Lid-Pulling Machine

● Ensures clean and safe lid surfaces for sealing.

● Reduces manual handling and contamination risk.

● Adjustable settings to suit different film thicknesses and barrel sizes.

● Removes dust and debris from barrel surfaces before filling.

● Enhances product appearance and hygiene.

● Works with various barrel dimensions and materials.

● Reduces labor costs while improving line efficiency.

● Detects impurities, cracks, or defects in barrels.

● Provides real-time feedback for quality control.

● Minimizes defective product shipment.

● Integrates with PLC for automatic rejection of faulty barrels.

Automatic Heat-Shrink Machine

● Protects products during storage and transport.

● Adjustable temperature and speed for different barrel sizes.

● Reduces material waste and improves packaging efficiency.

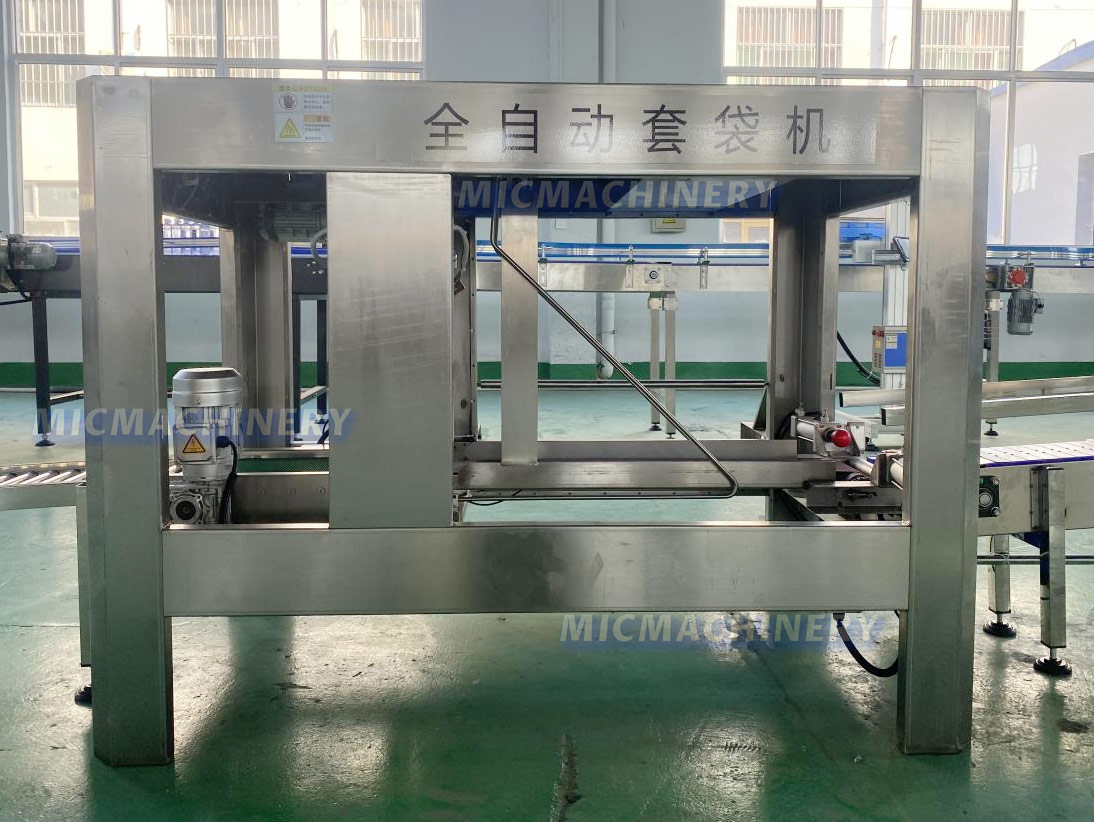

● Quickly covers barrels with protective bags for storage or delivery.

● Minimizes handling errors and labor requirements.

● Compatible with various bag sizes and materials.

● Enhances hygiene and product safety for end consumers.

Where Can This Technology Be Applied, and What Does the Future Hold?

Our barrel filling line can easily adapt to different operational environments. From small community stations to large industrial bottling facilities, the system handles multiple barrel sizes and production scales without compromising efficiency or hygiene. This flexibility allows barrel factories to respond quickly to market changes while maintaining consistent output of high-quality barreled water.

Driving Innovation in Barrel Filling

The future of drinking water production line technology focuses on sustainability and intelligence. IoT connectivity, AI inspection, energy-saving auxiliary devices, and remote monitoring are transforming traditional barrel operations. Factories adopting these technologies can enhance production efficiency, reduce operational risks, and ensure compliance with increasingly strict hygiene standards.

Ensuring Quality and Efficiency with Mic Machinery

Choosing Mic Machinery ensures your barrel factory achieves the perfect balance of precision, automation, and reliability. Our integrated drinking water production line guarantees that every barreled water product is clean, safe, and efficiently produced, giving operators confidence in their daily operations and long-term growth.

- Hot Sauce Filling Production Line

- Lube Oil Production Line

- Olive Oil Production Line

- Perfume Production Line

- Silicone Production Line

- Beer Production Line

- Tube Manufacturing Machine

- Filling Machine Manufacturer

- Visual Inspection Machine

- Bottle Blowing Machine

- Laser Coding Machine

- Aseptic Cold Filling Machine

- Fruit and Vegetable Processing Machinery Manufacturer

- Dairy Products Machinery

- Alcoholic Drink Production Equipment

- Commercial Water Treatment System

- Blowing Filling Capping Machine

- Barrel Filling Line